City & Guilds NPTC Units

Most City & Guilds, Lantra Awards Assessments and indeed training courses that we run start with a consideration of Risk Assessment. It takes time to develop a good understanding of the ideas around risk assessment. We’ve produced two articles on this topic, the first one pitched at a student or candidate starting out and looking to demonstrate understanding at a level appropriate to our entry level units to enable a confident start to assessments.

However, over time you may want to increase your knowledge around risk assessment so we have produced a more detailed study of the Management of Health & Safety at Work Regulations 1999 and what they require in Part 2 - enjoy!

We often mix up risk assessment and emergency planning in tree work and in this article emergency contingencies are excluded from the risk assessment discussion.

The Management of Health & Safety at Work Regulations 1999 require that a risk assessment is carried out amongst other things, and, at the craft or unit level, this is mainly framed around the 5 steps to risk assessment process.

Assessors can frame this as an open question, such as what can you tell me about the risk assessment process, or what is the risk assessment process or more specifically what are the five steps in the risk assessment process? The assessor isn’t really looking to have a detailed discussion on these steps, just confirm that you can remember the steps.

- Identify the hazards – specific to the site, task and machine

- Decide who might be harmed and how

- Evaluate the risks and decide on precautions

- Record your findings and implement them

- Review your assessment and update if necessary

Let’s have a more detailed look at the 5 steps and discuss them in the context of our industry.

Step One - Identify The Hazards

Hazards are anything that have the potential to cause harm. It doesn’t mean they necessarily will cause harm, only that they might. Examples of hazards are a weak tree structure or anchor point that might be used for tree access or the chainsaw chain moving at 20m/s in proximity to the operator’s leg.

Step Two - Decide Who Might Be Harmed And How

This step is about noting the people or groups of people that are at risk from the hazards identified in Step 1. It’s not just the obvious workers at risk, it could be members of the public in proximity to our tree work or perhaps maintenance staff onsite to fix a chipper. How the people could be harmed should also be noted, by detailing the hazardous event and possible injuries for each of the hazards identified in Step 1.

So, in the first example we can see that climbing on a weak anchor point that could fail when loaded (perhaps more heavily when a climber swings from one position to another) could result in a fall and the potential injuries suffered from such falls are broken bones, punctured lungs, head and brain damage.

Step Three - Evaluate The Risks And Decide On Precautions

Evaluating the risks means looking at both the likelihood of harm and the probable severity of that harm. It’s important not to forget the longer term or chronic health effects as there can be a tendency to focus on the immediate catastrophic type of incidents.

Risk can be rated using a scoring system and we’ll have a look at these in the second part of this article, but it’s worth noting they can be highly subjective and a possible distraction from the task of deciding what controls are required, that is the things we do in order to bring the likelihood of the hazard causing harm down or the severity of the harm down, or both.

Considering the first example of a climbing activity the likelihood of such an event is probably quite low but certainly possible as I’ve heard of many such falls in my time in the industry. The harm is very significant with life changing or ending consequences. From this we can reach an unsurprising conclusion that falling out of a tree is definitely something we would put effort into preventing.

Avoiding climbing entirely and working on the tree in another way will eliminate the risk of a climber falling following anchor point failure. Working on the tree in another way may not be risk free of course, only that the climbing risk has been eliminated. Perhaps we could choose to fence around the tree and exclude the public from it. Or fell it using a forestry harvester or excavator mounted grapple saw? If we decide to climb there would be a raft of controls including the use of wait for it… two anchor points.

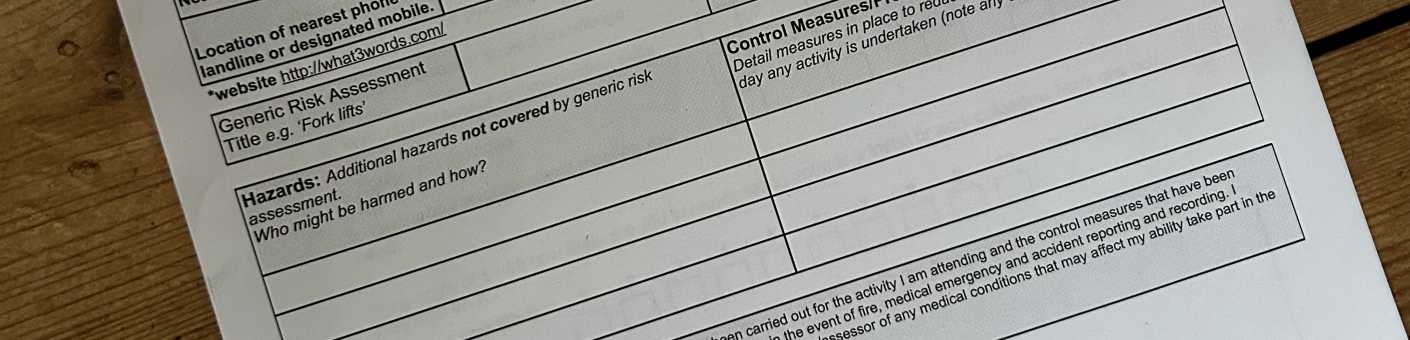

Step Four - Record The Significant Findings

The significant findings of the risk assessment should be recorded if there are more than 5 employees, with the detail proportionate to the level of risk and the complexity of the organisation or process. Key information would be about the hazards and the controls required.

Step Five - Review The Risk Assessment

Risk Assessments should be reviewed to ensure they remain valid, in response to changes in the work process, machines, workers or following an incident investigation.

Risk Assessment In Action

The next assessment question is deceptively short, it asks you to give examples of the hazards, risks and controls in the context of the site, task and machine. Operator was also in the City & Guilds list for a brief time

Historically this was often the answer that a candidate gave when asked anything about risk assessment related – they replied with a machine gun style delivery “sitetaskmachine”! City & Guilds varied the above for a while with the rather obtuse:

- Area to be worked on

- Work to be done

This was subsequently revised back to the site, task & machine a much more usable way of working for most people.

So, it’s the application of these steps in the context of the worksites, (could be the workshop, crosscutting yard or felling/climbing site) the activities that you might do (removing stumpgrinder teeth, selecting a final anchor point or severing an uprooted tree stem) and the machines that are being used (tractor, GRCS, top handled chainsaw). Let’s have a look in a bit more detail.

Site

We work on a variety of worksites but from an assessment point of view you are likely going to start out in a workshop. Hopefully the main hazards are well controlled, perhaps by the building design or regular testing so many students struggle to find the workshop hazards. Think about the electrical or heating system, the ease of escape in the event of a fire or slippery & cluttered surfaces. Crosscutting takes place in a yard area and felling in a woodland or field margin.

Task

Task refers to the activities we might get involved in such as chain sharpening, felling or stump grinding. A good tip is break this down into the smallest tasks imaginable such refuelling, or chain tensioning or cold starting or load testing a climbing system.

Machine

This includes the bigger machinery such as vehicles, chippers, winches or MEWPS but less obviously the smaller kit such as the GRCS or the electric chain sharpener.

Operator

This helps us to think about the type of operator in terms of level of experience or skill, attitudes or training. It can also include where an operator might be influenced by drink or drugs.

There’s a lot of overlap in the above, since most hazards will involve all three or four of our categories – but overlap is good, it prevents things from dropping through the gaps. The site, task machine & operator framework is a good way to help formalise our thinking and ensure hazards are not missed.

I often help develop a student’s understanding of the process by using a table to apply this:

| Step 1 Hazard – what can cause harm? | Step 2 Who is at risk and how? | Step 3 Controls – what can we do? – a selection of indicative controls – not exhaustive? |

|

Site Based

Terrain – complex, rutted, slopes, wet, slippery. Weather adverse, too hot, cold, wet, windy. Tree condition – Damaged, dead, diseased. Power Lines – energised powerlines in proximity to felling site. |

Students and instructor on site slip or trip. Bruising/fractures. Slip delays movement along prepared escape route. Crush or head damage. Climber suffers from hypothermia. Electric shock & burns/electrocution to chainsaw operator. |

Avoid steep or rutted ground, come back when the site is dry. Thoroughly prepare an escape route & use a dynamic stance when completing a final part of the felling cut. Avoid working on the worst wet, windy & cold days. Ensure climber has food, hot drinks and weatherproof insulating layers. Fell the tree as an alternative to sectional takedown. Contact District Network Operator & seek advice on safe working - possible shutdown. |

|

Task or Activity based

Throwline use – miss thrown pod strikes vehicle windscreen or groundcrew. Changeovers - misses harness attachment Branch walking with potential to swing into dead oak stub. Felling trees liable to split vertically. |

Climber - bruising or fracture to hand/forearm. Damaged property. Climber falls leads to climber falling from height multiple fracture such as pelvis. Climber fractures ribs and punctures lung. Chainsaw operator struck on head and knocked over or crushed. |

Avoid throwline use adjacent to vulnerable property. Use correct techniques & attachment knots. Thorough testing procedure for anchor point changeovers. Always 2 points of attachment. Gain high anchor points and use redirects to minimise potential swings. Deploy lanyard. Use telescopic pole saw to reach branch tips. Machine Fell. Assess tree prior to felling, species, condition & split potential. Correct cut choice. |

|

Machine based

Sharp chainsaw chain secured in vice in proximity to workshop door. Moving chainsaw chain in proximity to operators leg. Rotating brush cutter blade strikes stone. |

Visitors to workshop bash chain and cut their midsection. Chainsaw operator suffers severe lacerations behind type A trousers. Operator struck by stone fragment and loses sight in one eye. |

Relocate sharpening station away from high traffic zones. Only secure in vice whilst sharpening. Avoid chainsaw use by selling all harvester produced cordwood. Use a flail mower on large areas. Use serrated cord rather than plastic. Walk site to confirm safe to work. Remove stones. |