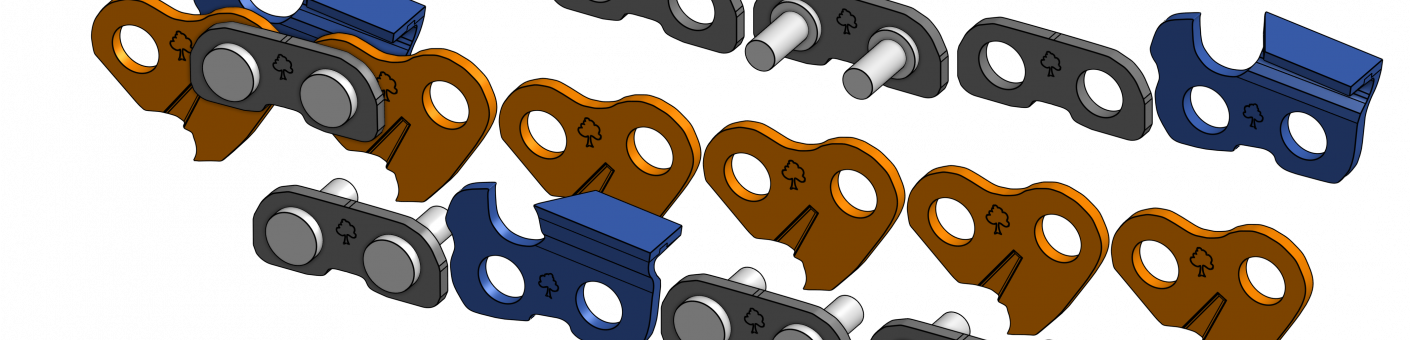

Chainsaw chains are made up of a range of components that in combination allow them to cut. The following basic description covers the key chain parts:

- Drive links

- Cutters

- Tie straps

- Rivets

Drive links are driven by the sprocket, maintain position and stability in the guide bar rails and pick up and distribute lubricating oil over the whole chain. Debris within the guide bar is also scraped out to maintain this oil coverage. Drive links are sandwiched between linking cutters and tie straps, the chain design dictating its exact layout or sequence.

Cutters are positioned on the outer part of the chain on both the left and right. They are the visible part of the chain when it is mounted on a guide bar.

Tie straps act the same way as the cutters connect the drive links. One side of these tie straps will be pre-set with rivets that form the flexible join.

Chainsaw chains work by removing the channel of woody material known as the chipper tooth principle. Each cutter contributes to the removal of tiny chips of wood as it moves around the guide bar between 16-22 meters per second.

Knowing the parts of the cutter is a great place to start in understanding this process, and building knowledge around the whole chain and later on sharpening.

Cutter parts detail image

- Chassis

- Top plate

- Side plate

- Working corner

- Gullet

- Rivet holes

- Heel

- Toe

- Depth gauge

- Witness mark

The depth gauge controls the extent to which the cutter engages with the wood since the cutter top plate slopes backwards slightly. The relative height between the top plate and the depth gauge will reduce following the sharpening so this needs to be monitored and maintained.

- Cutter profile – detailed in next article

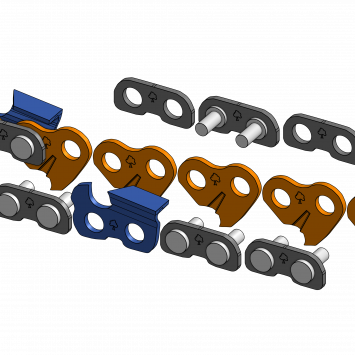

- Bumper drive links

- Ramped depth gauge

- Raised tie straps

Cutter profiles will be detailed in the next article, however, for now, it’s enough to know that a sharp full chisel profile, most often found on professional chains, is more liable to kickback.

Bumper drive links can have either a flat or curved top and can be identified by looking at the difference between the drive link shape in front of and behind any of the cutter links on the chain. Those in front are the ones that feed or lead the cutter into the material and they change angle relative to the cutter, as the chain rotates around the nose sprocket.

Ramped depth gauges are identifiable by a longer length and shallower angle on the depth gauge, which feeds the wood up to the cutter more gently compared to an abrupt or shorter depth gauge.

Finally, raised tie straps are a modified tie strap shape. These can be larger and broadly the same shape, or features a curved or double curved profile.

We specify a chain with a bumper drive link, a smooth ramped depth gauge and a semi-chisel cutter profile for our hire saws. They offer an excellent cutting performance, whilst giving confidence in a range of materials.